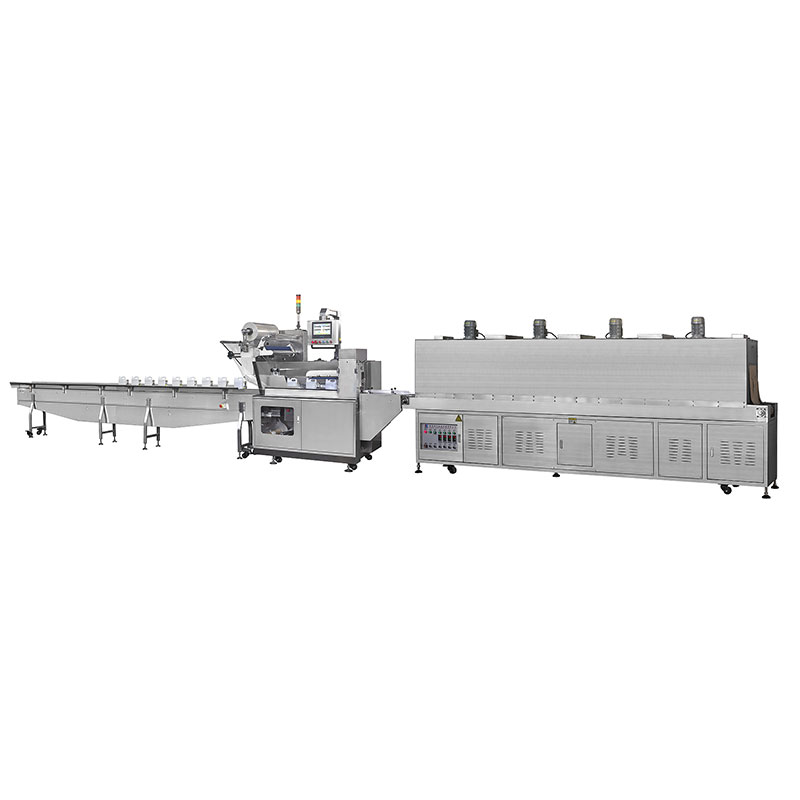

Automatic Pillow Packaging Machine

High-Speed Horizontal Flow Packaging Solution

The Automatic Pillow Packaging Machine is a fully automated horizontal flow packing system designed for high-speed pillow-type packaging. It automates the entire packaging process — including product feeding, film forming, sealing, and cutting — delivering consistent package quality, high production efficiency, and reduced operating costs for industrial production lines.

Typical Applications

Automatic Pillow Packaging Machines are widely used in industries where high-volume, consistent packaging is required:

Food Industry: snacks, biscuits, frozen foods, noodles

Household Products: soaps, wipes, disposable items

Agricultural Products: fruits, vegetables, seafood

Industrial Components: small parts, hardware accessories

Consumer Goods: retail-ready packaged items requiring pillow-style bags

Its versatility allows adaptation to different product shapes, sizes, and packaging materials.

Main features

- The machine is with very good synchronism, PLC control, Omron brand, Japan.

- Adopting photoelectric sensor to detect the eye mark, tracking fast and accurately

- Date coding is equipped within the price.

- Reliable and stable system, low maintenance, programmable controller.

- HMI display contains length of packing film, speed, output, temperature of packing etc.

- Adopt PLC control system, reduce mechanical contact.

- Frequency control, convenient and simple.

- Bidirectional automatic tracking, color control patch by photoelectric detection.

| Model SPA450/120 |

| Max Speed 60-150 packs/min

The speed depend on the shape and size of products and film used |

| 7” size digital display |

| People friend interface control for easy to operate |

| Double way tracing eye-mark for printing film, accurate control bag length by servo motor, this make operate convenient to run the machine ,save time |

| Film roll can be adjustable to guarantee the longitudinal sealing in line and perfect |

| Japan brand ,Omron photocell ,with long time durability and accurate monitoring |

| New design longitudinal sealing heating system ,guarantee stable sealing for center |

| With human friendly glass like cover on end sealing, to protect operate avoid of damage |

| 3 sets of Japan brand temperature control units |

| 60cm discharge conveyor |

| Speed indicator |

| Bag length indicator |

| All parts are stainless steel nos 304 pertaining on contacting the product |

| 3000mm in-feeding conveyor |

Quality & Compliance Standards

Constructed using food-grade stainless steel (SUS304)

Meets CE safety standards

Designed for compliance with industrial hygiene and safety regulations

Optional customization for ISO or other client-specific certification requirements

Why Choose Our Automatic Pillow Packaging Machine?

Increased Production Efficiency

Automates feeding, wrapping, sealing, and cutting, enabling high-speed, continuous operation and freeing operators for higher-value tasks.

Consistent Package Quality

Precision mechanisms ensure uniform bag formation, strong seals, and minimal defects, improving brand presentation and customer satisfaction.

Reduced Labor and Operational Costs

Automation lowers dependency on manual labor, reduces errors, and optimizes operational costs.

Optimized Material Usage

Accurate film control minimizes material waste, lowering cost per unit while maintaining professional package aesthetics.

Technical Specification

|

Model |

SPA450/120 |

|

Max film width(mm) |

450 |

|

Packaging rate(bag/min) |

60-150 |

|

Bag length(mm) |

70-450 |

|

Bag width(mm) |

10-150 |

|

Product height(mm) |

5-65 |

|

Power voltage(v) |

220 |

|

Total installed power(kw) |

3.6 |

|

Weight(kg) |

1200 |

|

Dimensions (LxWxH) mm |

5700*1050*1700 |

FAQs

Q1: Can this machine handle fragile or irregular-shaped products?

A1: Yes, adjustable film tension and feeding mechanisms ensure gentle handling while maintaining package integrity.

Q2: What industries can use this machine?

A2: Suitable for food, consumer goods, pharmaceuticals, agricultural products, and industrial components.

Q3: Is maintenance difficult?

A3: No, the machine is designed for easy cleaning, with accessible components and clear maintenance instructions.

Q4: Can the machine integrate into a complete packaging line?

A4: Yes, optional conveyors, checkweighers, and coding devices enable full-line integration.