Automatic Milk Powder Canning Line

Product Video

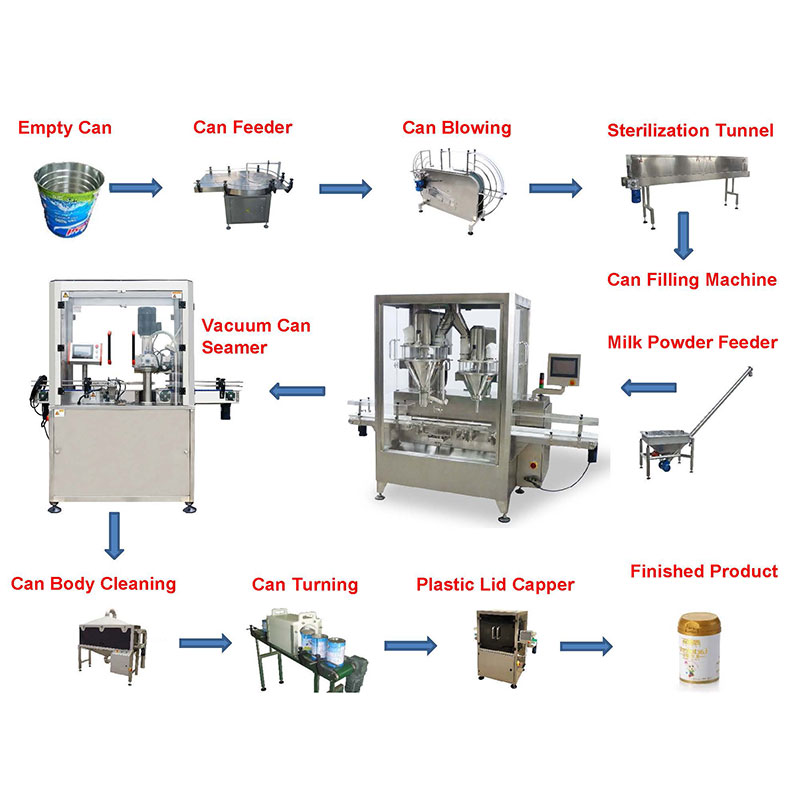

Basic Composition of Milk Powder Can Filling Line

The completed milk powder canning line generally includes de-palletizer, can unscrambling machine, can degaussing machine, can sterilization tunnel, double filler powder filling machine, vacuum seamer, can body cleaning machine, laser printer, plastic lid capping machine, palletizer and etc., which can realize automatic packaging process from the milk powder empty cans to the finished product.

Milk Powder Filling Canning Line Sketch Map

Features of Automatic Milk Powder Canning Line

1. High-Precision Spiral Metering Filling

Utilizing an advanced spiral metering filling system, this line precisely measures the exact quantity of milk powder for each can, effectively reducing product loss and ensuring uniform weight distribution. The servo motor-driven spiral mechanism provides smooth and stable powder delivery, suitable for powders with different flow characteristics.

2. Vacuum Sealing Technology

Equipped with a vacuum sealing system, the line removes excess air before sealing, preventing oxidation and moisture ingress. This technology extends the shelf life of milk powder and preserves its freshness and nutritional value.

3. Fully Automated Operation

From can feeding, cleaning, filling, vacuum sealing, to coding and palletizing, the entire process is fully automated. The system employs PLC control and a user-friendly HMI interface for real-time monitoring, parameter setting, and fault diagnosis, greatly improving operational efficiency.

4. Hygienic and Easy to Clean

The modular design facilitates quick disassembly and cleaning, supporting CIP (Clean-In-Place) and SIP (Sterilization-In-Place) processes. The design prevents powder accumulation and cross-contamination, ensuring compliance with strict food safety regulations and maintaining product quality over time.

4. Certified Quality and Compliance

Shipu’s canning line complies with international certifications including CE, ISO9001, and GMP standards, guaranteeing that the equipment meets rigorous quality and safety requirements. All components contacting the product are made from food-grade stainless steel (SUS304/SUS316L), ensuring hygiene and preventing contamination.

5. Adaptability & Versatility

The system supports a wide range of can sizes, including tinplate, aluminum, and composite cans with different diameters and heights. It is compatible with various milk powder formulations and other powdered dairy products.

6. Integrated Quality Control

Equipped with weight checkers, leak detectors, and metal detectors, the line ensures that only cans meeting quality standards proceed to packaging, reducing defective rates and improving product reliability.

5. Intelligent Control and User-Friendly Interface

The entire line is controlled by an advanced PLC system with a touchscreen HMI, enabling easy parameter setting, real-time monitoring, automatic fault detection, and data logging. This intelligent system reduces downtime and simplifies operator training.

6. Flexible Compatibility and Scalability

Shipu’s production line is compatible with various can sizes and materials, with easy format changeover, adapting quickly to different product specifications and market demands. The modular structure also allows for future upgrades, including integration with upstream or downstream packaging equipment.

The Working Principle of Automatic Milk Powder Canning Filling Line

1. First place the empty milk powder cans on the rotary bottle unscrambler, which will rotate to bring the cans into the conveyor belt one by one.

2. The tank cleaning machine will blow the empty tank to remove dust to ensure that there is no impurities in the tank.

3. Then the empty cans enter the sterilization tunnel, and in the process, the empty cans after UV sterilization and sterilization will be obtained.

4. The high-precision milk powder filling machine fills the milk powder into the milk powder tank after weighing.

5. Enter the vacuum nitrogen filling and sealing machine, according to the high-purity canning requirements of milk powder and protein powder, ensure that the residual oxygen rate is less than 2%, automatically cover the can, automatically vacuumize, automatically fill nitrogen, and automatically seal the can without pollution.

6. After sealing the can, clean the can body.

7. Since the milk powder filling is carried out from the bottom, the milk powder tank needs to be rotated.

8. Put on the plastic cover,

9. Complete the filling of the milk powder can.

Automatic Milk Powder Canning Line Technical Specifications

| Feature | Details |

| Production Capacity | Up to 2000 cans per hour |

| Filling Accuracy | ±1-2 grams |

| Can Diameter Range | 50 mm – 120 mm |

| Can Height Range | 80 mm – 180 mm |

| Control System | PLC with touchscreen HMI |

| Material in Contact | Food-grade stainless steel (SUS304/SUS316L) |

| Certifications | CE, ISO9001, GMP compliant |

Our Advantage in Dairy Industry

Are you looking for a fully automatic milk powder filling line? Shipu provides high quality and high precision fully automatic tin cans milk powder canning line. The milk powder cans can be packaged from 73mm to 189mm in diameter. During the past 18 years, we have built long term cooperation with world outstanding enterprises, like Fonterra, Nestle, Yili, Mengniu and etc. Welcome to contact us, we look forward to working with you!

Benefits of Using Automatic Milk Powder Canning Line

Improve Production Efficiency: High-speed automation boosts throughput while maintaining stable product quality.

Reduce Labor Costs: Minimizes manual intervention with intelligent controls and fault detection.

Ensure Product Quality & Safety: Vacuum sealing and hygienic design protect milk powder from contamination and spoilage.

Minimize Material Waste: Precise spiral filling reduces overfilling and product loss.

Flexible Operation: Suitable for small to large-scale production with easy format changeover.

Seamless Integration: Compatible with upstream and downstream packaging lines for full production automation.

Why Choose Shipu Automatic Milk Powder Canning Line?

Rich Industry Experience

With over a decade of dedicated focus on automatic canning systems, Shipu has accumulated extensive expertise in designing, manufacturing, and customizing milk powder packaging lines that meet diverse production needs worldwide.

Cutting-Edge Technology & Innovation

Shipu invests heavily in R&D to incorporate the latest servo-driven spiral metering, vacuum sealing, and intelligent PLC control systems into its canning lines, ensuring superior filling accuracy, operational stability, and automation levels.

Strict Quality Control & Certified Standards

As a manufacturer, Shipu maintains rigorous quality assurance processes, producing equipment that complies with international certifications such as CE, ISO9001, and GMP. All product-contact components use food-grade stainless steel, guaranteeing safety and hygiene.

Customized Solutions for Diverse Needs

Understanding that every dairy manufacturer has unique requirements, Shipu offers tailor-made canning lines adaptable to different powder types, can sizes, and production capacities, providing flexible configurations from entry-level to fully automated high-speed lines.

Integrated Manufacturing & After-Sales Support

As a one-stop manufacturer, Shipu controls the entire production process—from component fabrication to assembly—ensuring timely delivery and consistent quality. The company also provides comprehensive after-sales services, including installation, training, and ongoing technical support.

Global Reach and Proven Track Record

Shipu’s automatic milk powder canning lines are trusted by clients across multiple continents, demonstrating reliability in various operational environments and compliance with local and international market standards.

FAQ: Automatic Milk Powder Canning Line

1. What types of milk powder can be packaged with the automatic canning line?

Our automatic milk powder canning line can handle a wide range of powdered dairy products, including infant formula, nutritional milk powder, skimmed and whole milk powders, protein powders, and specialized dietary powders.

2. What is the production capacity of the milk powder canning line?

The line can achieve production speeds of up to 2000 cans per hour, depending on the can size, powder properties, and specific configuration.

3. How accurate is the Automatic Milk Powder filling system?

The spiral metering filling technology ensures high accuracy with a typical tolerance of ±1-2 grams per can, which helps minimize product waste and maintain consistent product quality.

4. Can the Automatic Milk Powder Canning Line handle different can sizes and materials?

Yes, the system is compatible with various can diameters and heights, and supports metal, aluminum, and composite cans. Format changeovers are quick and easy to reduce downtime.

5. Is the equipment easy to clean and maintain?

Absolutely. The design incorporates food-grade stainless steel with modular components that support quick disassembly, cleaning-in-place (CIP), and sterilization-in-place (SIP) to meet strict hygiene standards.

6. What level of automation does the Automatic Milk Powder Canning Line offer?

The line is fully automatic, covering can feeding, filling, sealing, coding, inspection, and palletizing, with intelligent PLC control and touchscreen HMI for easy operation and monitoring.

7. Can the Automatic Milk Powder Canning Line be customized for specific production needs?

Yes, the production line can be tailored to fit specific powder characteristics, production capacity, packaging requirements, and integration with existing production setups.

Through the processing technology of the vacuum and nitrogen flushing, the residual oxygen can be controlled within 2%, so as to ensure the shelf life of the product to be 2-3 years. At the same time, the tinplate can packaging also has the characteristics of pressure and moisture resistance, to be suitable for long-distance transportation and long-term storage.

The packaging specifications of canned milk powder can be divided into 400 grams, 900 grams of conventional packaging and 1800 grams and 2500 grams of family promotion packaging. Milk powder manufacturers can change the production line mold to pack different specifications of product.

Milk powder is a difficult product to fill. It can exhibit different filling properties depending on formulation, fat content, drying method, granulation and density ratio. Even for the same product, its characteristics can vary depending on the manufacturing conditions. We professionally develop and design professional powder filling machines to meet the different needs of users. Please send us your requirements and we will give you a satisfactory solution for milk powder filling line.