Automatic Milk Powder Canning Line

Product Video

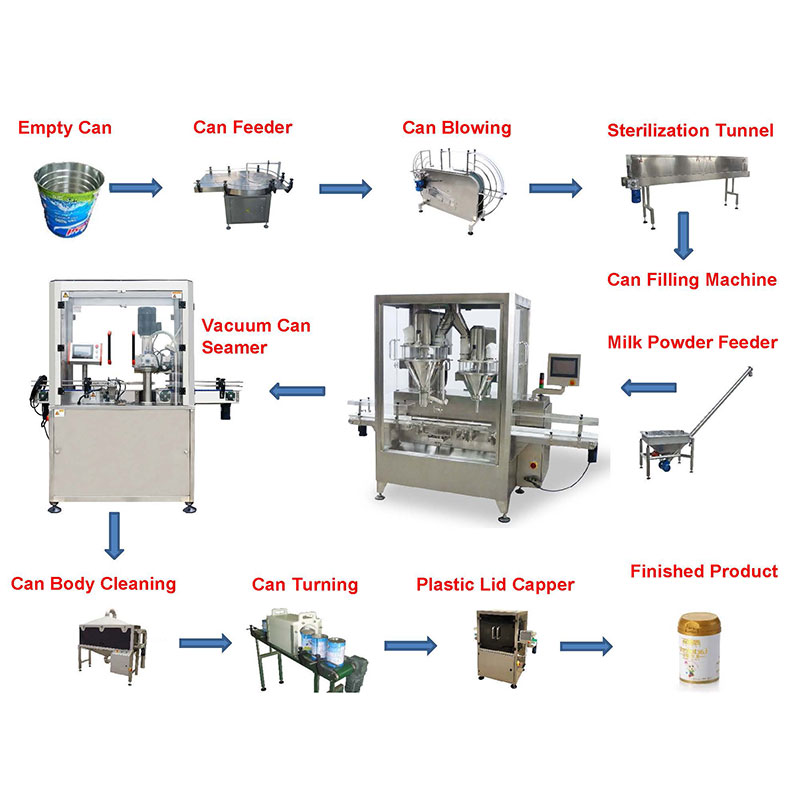

Basic Composition of Milk Powder Can Filling Line

The completed milk powder canning line generally includes de-palletizer, can unscrambling machine, can degaussing machine, can sterilization tunnel, double filler powder filling machine, vacuum seamer, can body cleaning machine, laser printer, plastic lid capping machine, palletizer and etc., which can realize automatic packaging process from the milk powder empty cans to the finished product.

Milk Powder Filling Canning Line Sketch Map

Features of Tin Can Milk Powder Filling Line

1. The whole machine is made of stainless steel in accordance with food hygiene standards.

2. Use screw metering to complete metering, filling, etc., suitable for metering different types of powder materials.

3. Using servo drive system, auger filler fills milk powder with high precision and stable performance.

4. Open material box, easy to clean.

5. Fully sealed air resistance glass stainless steel, dust does not leak, and the filling port is equipped with a dust collection device to protect the workshop environment.

6. Complete all packaging processes such as measuring, feeding, filling, bag making, and printing dates.

The Working Principle of Automatic Milk Powder Canning Filling Line

1. First place the empty milk powder cans on the rotary bottle unscrambler, which will rotate to bring the cans into the conveyor belt one by one.

2. The tank cleaning machine will blow the empty tank to remove dust to ensure that there is no impurities in the tank.

3. Then the empty cans enter the sterilization tunnel, and in the process, the empty cans after UV sterilization and sterilization will be obtained.

4. The high-precision milk powder filling machine fills the milk powder into the milk powder tank after weighing.

5. Enter the vacuum nitrogen filling and sealing machine, according to the high-purity canning requirements of milk powder and protein powder, ensure that the residual oxygen rate is less than 2%, automatically cover the can, automatically vacuumize, automatically fill nitrogen, and automatically seal the can without pollution.

6. After sealing the can, clean the can body.

7. Since the milk powder filling is carried out from the bottom, the milk powder tank needs to be rotated.

8. Put on the plastic cover,

9. Complete the filling of the milk powder can.

Our Advantage in Dairy Industry

Are you looking for a fully automatic milk powder filling line? Shipu provides high quality and high precision fully automatic tin cans milk powder canning line. The milk powder cans can be packaged from 73mm to 189mm in diameter. During the past 18 years, we have built long term cooperation with world outstanding enterprises, like Fonterra, Nestle, Yili, Mengniu and etc. Welcome to contact us, we look forward to working with you!

Through the processing technology of the vacuum and nitrogen flushing, the residual oxygen can be controlled within 2%, so as to ensure the shelf life of the product to be 2-3 years. At the same time, the tinplate can packaging also has the characteristics of pressure and moisture resistance, to be suitable for long-distance transportation and long-term storage.

The packaging specifications of canned milk powder can be divided into 400 grams, 900 grams of conventional packaging and 1800 grams and 2500 grams of family promotion packaging. Milk powder manufacturers can change the production line mold to pack different specifications of product.

Milk powder is a difficult product to fill. It can exhibit different filling properties depending on formulation, fat content, drying method, granulation and density ratio. Even for the same product, its characteristics can vary depending on the manufacturing conditions. We professionally develop and design professional powder filling machines to meet the different needs of users. Please send us your requirements and we will give you a satisfactory solution for milk powder filling line.