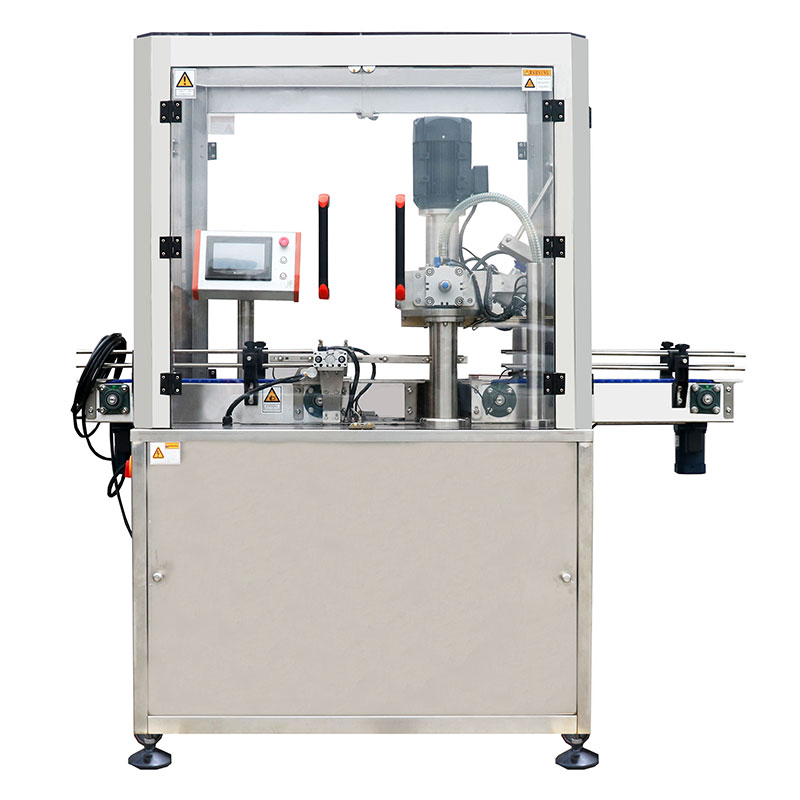

Automatic Vacuum Can Seamer

Technical Specification

- Sealing diameterφ40~φ127mm,sealing height 60~200mm;

- Two working modes are available: vacuum nitrogen sealing and vacuum sealing;

- In the vacuum and nitrogen filling mode, the residual oxygen content can reach less than 3% after sealing, and the maximum speed can reach 6 cans / minute (the speed is related to the size of the tank and the standard value of the residual oxygen value)

- Under vacuum sealing mode, it can reach 40kpa ~ 90Kpa negative pressure value, speed 6 to 10 cans / min;

- The overall appearance material is mainly made of stainless steel 304, with a thickness of 1.5mm;

- Plexiglass material adopts imported acrylic, thickness 10mm, high-end atmosphere;

- Use 4 rollers cans for rotary sealing, the sealing performance index is excellent;

- Use PLC intelligent program design plus touch screen control, easy to use and set up;

- There is lack lid alarm prompting function to ensure efficient and uninterrupted work of the equipment;

- No cover, no sealing and failure detection shutdown, effectively reducing equipment failure;

- The drop lid part could add 200 pieces at a time (one tube);

- Change can diameter need to change mould, the replacement time is about 40 minutes;

- Change can diameter need to change mould:chuck+clamp can part+drop lid part,different material can and lid need to change roller;

- change can height,it do not need to change mould,adopt hand-screw design, effectively reduce the fault, the adjustment time is about 5 minutes;

- Strict testing methods are used to test the sealing effect before delivery and delivery to ensure product quality;

- The defect rate is extremely low, iron cans are less than 1 in 10,000, plastic cans are less than 1 in 1,000, paper cans are less than 2 in 1,000;

- The chuck is quenched with chromium 12 molybdenum vanadium, the hardness is more than 50 degrees, and the service life is more than 1 million cans;

- The rolls is imported from Taiwan. The hob material is SKD Japanese special mold steel, with a life span of more than 5 million seals;

- Configure the conveyor belt with a length of 3 meters, a height of 0.9 meters, and a chain width of 185mm;

- Size: L1.93m*W0.85m*H1.9m,packaging size L2.15m×H0.95m×W2.14m;

- Main motor power 1.5KW / 220V, vacuum pump power 1.5KW / 220V, conveyor belt motor 0.12KW / 220V total power: 3.12KW;

- The net weight of the equipment is about 550KG, and the gross weight is about 600KG;

- Conveyor belt material is nylon POM;

- The air compressor needs to be configured separately. The power of the air compressor is above 3KW and the air supply pressure is above 0.6Mpa;

- If you need to evacuate and fill the tank with nitrogen, you need to connect with an external nitrogen gas source, the gas source pressure is above 0.3Mpa;

- The equipment is already equipped with a vacuum pump, no need to purchase separately.

Write your message here and send it to us