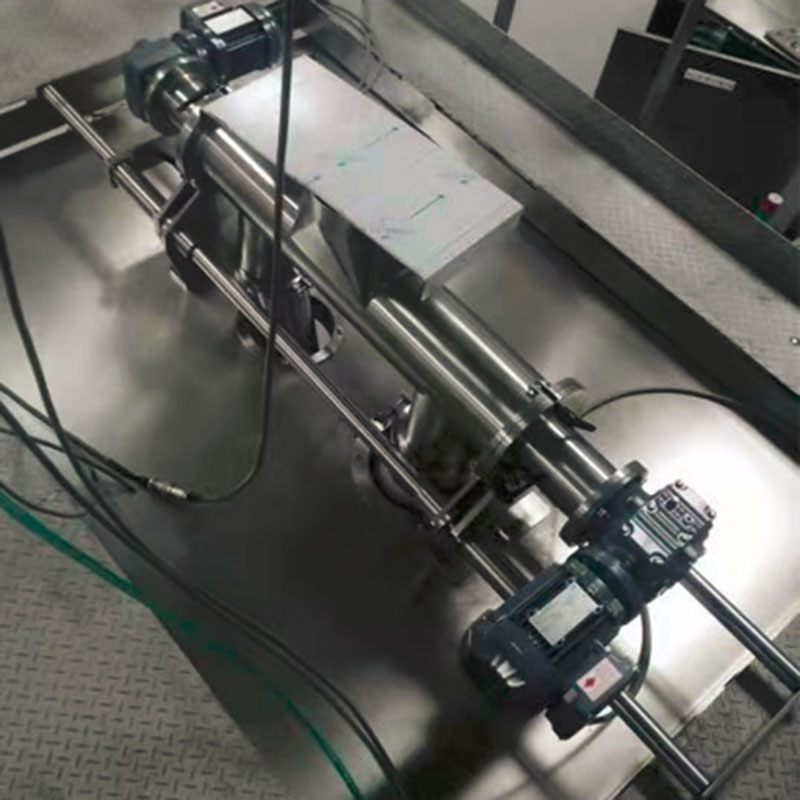

Double Spindle paddle blender

Main Features

- The mixing time, discharging time and mixing speed can be set and displayed on the screen;

- The motor can be started after pouring the material;

- When the lid of the mixer is opened, it will stop automatically; when the lid of the mixer is open, the machine cannot be started;

- After the material is poured, the dry mixing equipment can start and run smoothly, and the equipment does not shake when starting;

- The cylinder plate is thicker than normal, and other materials should also be thicker.

(1) Efficiency: The relative reverse spiral drives the material to be thrown at different angles, and the mixing time is 1 to 5 minutes;

(2) High uniformity: the compact design makes the blades rotate to fill the chamber, and the mixing uniformity is as high as 95%;

(3) Low residue: the gap between the paddle and the cylinder is 2~5 mm, and the open discharge port;

(4) Zero leakage: patented design ensures zero leakage of the shaft and discharge port;

(5) No dead angle: all the mixing bins are fully welded and polished, without any fasteners such as screws and nuts;

(6) Beautiful and atmospheric: Except for the gear box, direct connection mechanism and bearing seat, the other parts of the whole machine are all made of stainless steel, which is exquisite and atmospheric.

Technical Specification

| Model | SP-P1500 |

| Effective volume | 1500L |

| Full volume | 2000L |

| Loading factor | 0.6-0.8 |

| Rotating speed | 39rpm |

| Total weight | 1850kg |

| Total powder | 15kw+0.55kw |

| Length | 4900mm |

| Width | 1780mm |

| Height | 1700mm |

| Powder | 3phase 380V 50Hz |

Deploy List

- Motor SEW, power 15kw; reducer, ratio 1:35, speed 39rpm, domestic

- Cylinder and solenoid valve are FESTO brand

- The thickness of the cylinder plate is 5MM, the side plate is 12mm, and the drawing and fixing plate is 14mm

- With frequency conversion speed regulation

- Schneider low voltage electrical appliances