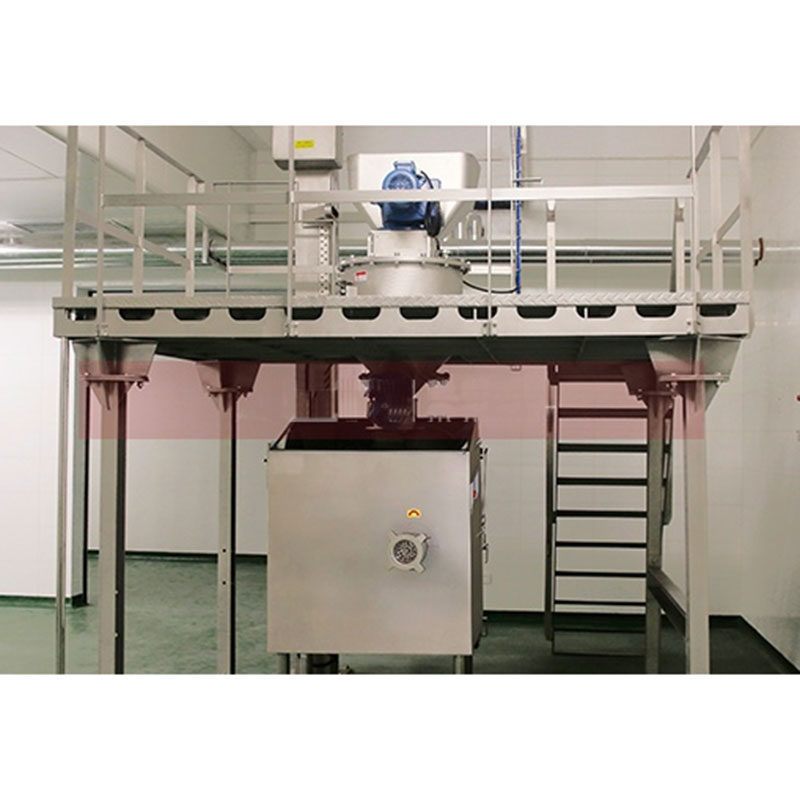

Automatic bag slitting and Batching station

Main Features

- The feeding bin cover is equipped with a sealing strip, which can be disassembled and cleaned. The design of the sealing strip is embedded, and the material is pharmaceutical grade;

- The outlet of the feeding station is designed with a quick connector, and the connection with the pipeline is a portable joint for easy disassembly;

- The control cabinet and control buttons are well sealed to prevent dust, water and moisture from entering;

- There is a discharge port to discharge the unqualified products after sieving, and the discharge port needs to be equipped with a cloth bag to pick up the waste;

- A feeding grid needs to be designed at the feeding port, so that some agglomerated materials can be broken manually;

- Equipped with a stainless steel sintered mesh filter, the filter can be cleaned with water and is easy to disassemble;

- The feeding station can be opened as a whole, which is convenient for cleaning the vibrating screen;

- The equipment is easy to disassemble, no dead angle, easy to clean, and the equipment meets the requirements of GMP;

- With three blades, when the bag slides down, it will automatically cut three openings in the bag.

Technical Specification

- Discharging Capacity: 2-3 Tons/Hour

- Dust-exhausting filter: 5μm SS sintering net filter

- Sieve diameter:1000mm

- Sieve Mesh size:10 mesh

- Dust-exhausting power: 1.1kw

- Vibrating motor power: 0.15kw*2

- Power Supply:3P AC208 - 415V 50/60Hz

- Total Weight: 300kg

- Overall Dimensions:1160×1000×1706mm

Write your message here and send it to us