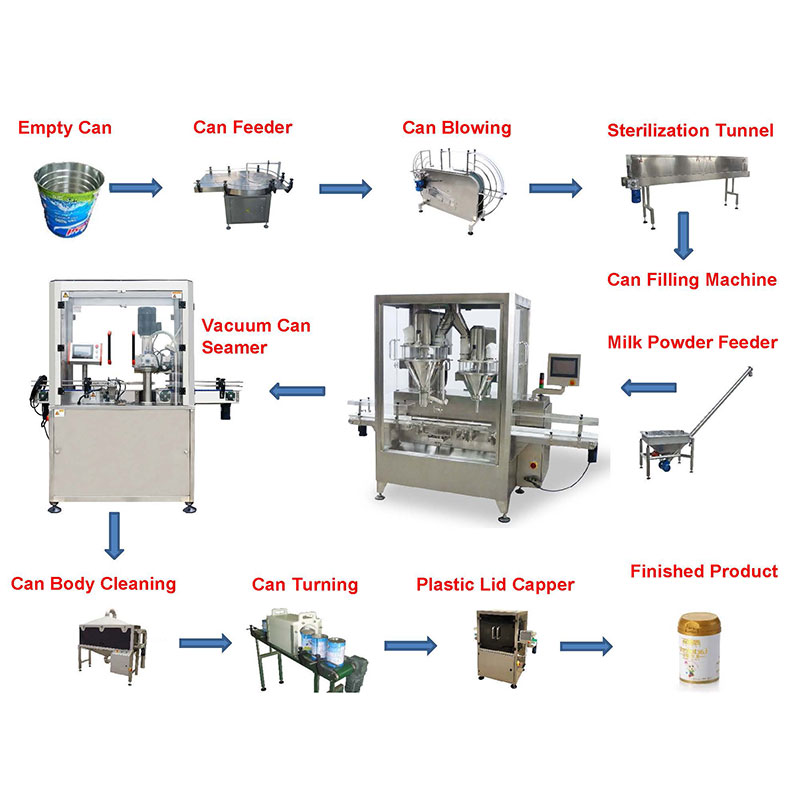

Automatic Milk Powder Can Filling Machine

Main features

- One line dual fillers, Main & Assist filling to keep work in high-precision.

- Can-up and horizontal transmitting is controlled by servo and pneumatic system, be more accurate, more speed.

- Servo motor and servo driver control the screw, keep stable and accurate

- Stainless steel structure, Split hopper with polishing inner-out make it to cleaned easily.

- PLC & touch screen make it be easy of operation.

- Fast-respond weighing system make the strongpoint to real

- The handwheel make the exchange of different filings to be easily.

- Dust-collecting cover meet the pipeline and protect environment to pollution.

- Horizontal straight design make the machine in little area

- Settled screw setup make no metal pollution in producing

- Process: can-into → can-up → vibration → filling → vibration → vibration → weighing & tracing → reinforce → weight checking → Can-out

- With whole system central control system.

Technical Specification

| Model | SP-W12-D140 | SP-W12-D210 |

| Dosing mode | Dual filler filling with online weighing | Dual filler filling with online weighing |

| Filling Weight | 100 - 1500g | 100 – 5000g |

| Container Size | Φ60-140mm; H 60-260mm | Φ60-210mm; H 60-260mm |

| Filling Accuracy | 100-500g, ≤±1g; 500-1000g,≤±2g; >1000g, ≤±3-4g | 100-500g, ≤±1g; 500-1000g,≤±2g; >1000g, ≤±3-4g |

| Filling Speed | 45 cans/min (#502) | 35 cans/min (#603) |

| Power Supply | 3P AC208-415V 50/60Hz | 3P, AC208-415V, 50/60Hz |

| Total Power | 3.4 kw | 4.75kw |

| Total Weight | 450kg | 650kg |

| Air Supply | 0.2cbm/min, 0.6Mpa | 0.2cbm/min, 0.6Mpa |

| Overall Dimension | 2650×1075×2683mm | 3200x1170x2920mm |

| Hopper Volume | 50L(Main) 11L (Assist) | 75L(Main) 25L (Assist) |

Write your message here and send it to us