Automatic Powder Packaging Machine

Automatic Powder Packaging Machine Introduction

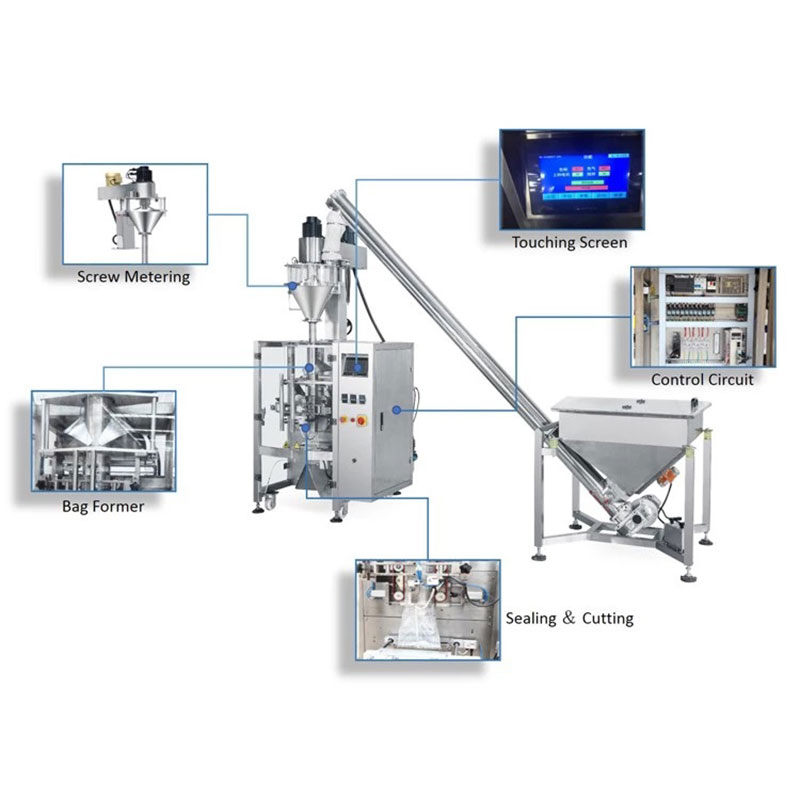

The automatic powder packaging machine is a highly efficient and versatile solution designed for precise filling and sealing of various powder and granule products. Equipped with advanced servo-driven feeding, PLC control, and intelligent safety systems, it ensures accurate dosing, stable performance, and consistent packaging quality. Its wide applicability makes it suitable for industries such as food, nutrition, chemicals, and pharmaceuticals. With features like automatic film correction, date coding, and optional gas flushing, this machine streamlines production, reduces material waste, and enhances overall operational efficiency.

Advantages of Shipu Automatic Powder Packaging Machine

In powder packaging, manufacturers often face challenges such as inconsistent filling accuracy, dust pollution, low production efficiency, and high material waste. Traditional manual or semi-automatic methods struggle to meet the demands of today’s fast-paced production environments. The Shipu automatic powder packaging machine addresses these pain points with servo-driven precision filling, PLC-controlled operations, and automatic film correction to ensure consistent, high-quality packaging. With features like optional gas flushing, integrated date coding, and intelligent safety systems, it provides a reliable, efficient, and hygienic packaging solution for a wide range of powder and granular products.

Automatic Powder Packaging Machine Applications Industries

Shipu’s automatic powder packaging machines are engineered to handle diverse powder and granule products, making them ideal for multiple industries:

Food & Beverages: Milk powder, protein powder, instant coffee, cocoa powder, spices, sugar

Nutritional Products: Health supplements, dietary powders, fortified food ingredients

Chemicals & Industrial Powders: Fine chemicals, mineral powders, detergents

Pharmaceuticals: Medicinal powders, baby formula, nutraceutical blends

This versatility makes it a perfect fit for manufacturers looking to scale production and standardize packaging quality.

Main features

Servo drive for film feeding

Synchronous belt by servo drive is more better to avoid the inertia, make sure the film feeding to be more exact, and longer working life and more steady operation.

PLC control system

Program store and search function.

Almost all the operation parameter (such as feeding length, sealing time and speed) could be adjusted, stored and callout.

7 inch touch screen, easy operation system.

The operation is visible for sealing temperature, packaging speed, film feeding status, alarm, bagging count and other main function, such as manual operation, test mode, time & parameter setting.

Film feeding

Open film feeding frame with color mark photo-electricity, automatic correction function to make sure roll film, forming tube and vertical sealing is in the same line, which to reduce material waste. No need to open vertical sealing when correction to save operation time.

Forming tube

Completed set of forming tube for easy and fast changing.

Pouch length auto tracking

Color mark sensor or encoder for auto tracking and length recording, make sure the feeding length will match the setting length.

Heat coding machine

Heat coding machine for auto coding of date and batch.

Alarm and safety setting

Machine stop automatically when door open, no film, no coding tape and etc., to guarantee the safety of operator.

Easy operation

The bag packing machine can match most of balance and measuring system.

Easy and fast to change wearing parts.

Technical specification

| Model | SPB-420 | SPB-520 | SPB-620 | SPB-720 |

| Film width | 140~420mm | 180-520mm | 220-620mm | 420-720mm |

| Bag width | 60~200mm | 80-250mm | 100-300mm | 80-350mm |

| Bag length | 50~250mm | 100-300mm | 100-380mm | 200-480mm |

| Filling range | 10~750g | 50-1500g | 100-3000g | 2-5kg |

| Filling accuracy | ≤ 100g, ≤±2%;100 - 500g, ≤±1%; >500g, ≤±0.5% | ≤ 100g, ≤±2%;100 - 500g, ≤±1%; >500g, ≤±0.5% | ≤ 100g, ≤±2%;100 - 500g, ≤±1%; >500g, ≤±0.5% | ≤ 100g, ≤±2%;100 - 500g, ≤±1%; >500g, ≤±0.5% |

| Packing Speed | 40-80bpm on PP | 25-50bpm on PP | 15-30bpm on PP | 25-50bpm on PP |

| Install Voltage | AC 1phase, 50Hz, 220V | AC 1phase, 50Hz, 220V | AC 1phase, 50Hz, 220V | |

| Total Power | 3.5kw | 4kw | 4.5kw | 5.5kw |

| Air Consumption | 0.5CFM @6 bar | 0.5CFM @6 bar | 0.6CFM @6 bar | 0.8CFM @6 bar |

| Dimensions | 1300x1240x1150mm | 1550x1260x1480mm | 1600x1260x1680mm | 1760x1480x2115mm |

| Weight | 480kg | 550kg | 680kg | 800kg |

Why Choose Shipu?

Enhanced Accuracy & Speed – Servo-driven feeding ensures precise weighing with minimal deviation.

Reduced Material Waste – Automatic alignment control saves packaging film and lowers production costs.

Seamless Integration – Easily adapts to existing production lines and supports customization.

Operator-Friendly Design – Touchscreen controls, parameter memory, and quick part replacement minimize downtime.

Built-In Safety & Traceability – Automatic alarms, date coding, and gas flushing enhance quality and compliance.

With Shipu advanced packaging solutions, businesses can achieve higher efficiency, better quality, and reduced operational costs.